françaisfr

françaisfr

françaisfr

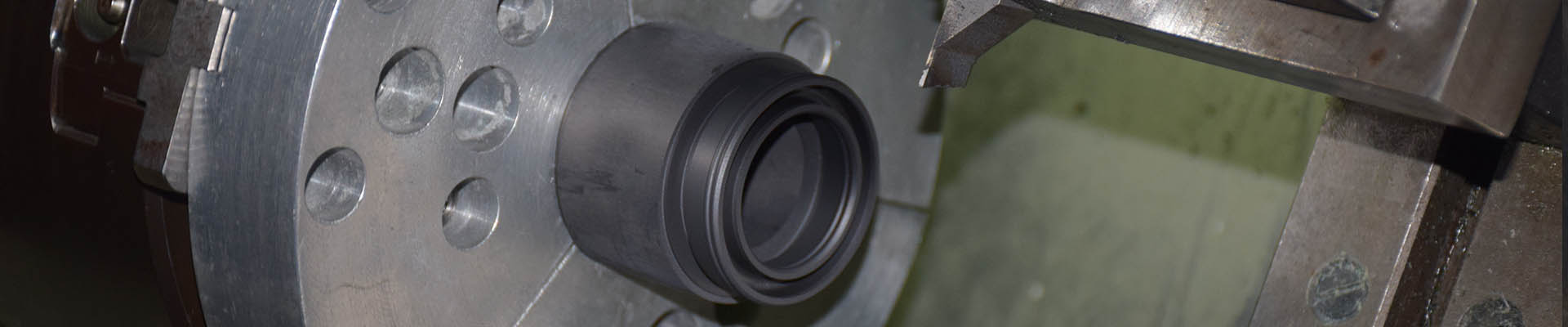

françaisfrApplication et fonction des joints d'étanchéité de tige de soupape

joints d'étanchéité de la tige de soupape sont utilisés dans les vannes pour assurer l'étanchéité autour de la tige de vanne (l'axe qui commande l'ouverture et la fermeture de la vanne). Ils sont essentiels pour empêcher les fuites de fluide ou de gaz, garantissant ainsi l'absence de fuites de pression et de contaminants. L'application de joints d'étanchéité de la tige comprend :

Contrôle de la pression : Elles contribuent à maintenir la pression à l'intérieur de la vanne, empêchant les fuites et assurant un bon fonctionnement dans des conditions de pression variables.

Étanchéité dans différents fluides : Les garnitures d'étanchéité de tige de soupape sont utilisées dans les vannes qui manipulent différents types de fluides, tels que l'eau, le pétrole, le gaz, la vapeur, les produits chimiques et même des substances agressives ou dangereuses.

Résistance à la température : Ces joints sont conçus pour résister à différentes plages de températures, ce qui les rend adaptés aux applications à haute ou basse température, telles que les systèmes à vapeur ou cryogéniques.

Prévention des fuites : Son objectif principal est d'empêcher les fuites du fluide contrôlé par la vanne, garantissant ainsi la sécurité et l'efficacité du système.

Applications :

1. Tuyaux : Utilisés dans les vannes de pipeline pour contrôler le débit et éviter les fuites.

2. Centrales électriques : Pour contrôler les flux de vapeur, de gaz ou d'eau.

3. Pétrole et gaz : Dans les procédés d'extraction et de raffinage où l'étanchéité est essentielle.

4. Traitement chimique : Lorsque les vannes contrôlent des substances potentiellement dangereuses ou corrosives.

Ces joints sont conçus pour fonctionner efficacement avec les systèmes de vannes manuels et automatisés. Le matériau et la conception du joint peuvent varier en fonction du type de fluide, de la température et de la pression auxquels la vanne est exposée.

Nouveau blog

© droits dauteur: 2026 Guangzhou JST Seals Technology Co., Ltd. Tous les droits sont réservés.

Numériser vers WeChat