françaisfr

françaisfr

françaisfr

françaisfrQuelle est la différence et les avantages entre la bague de support PEEK et la bague de support PTFE ?

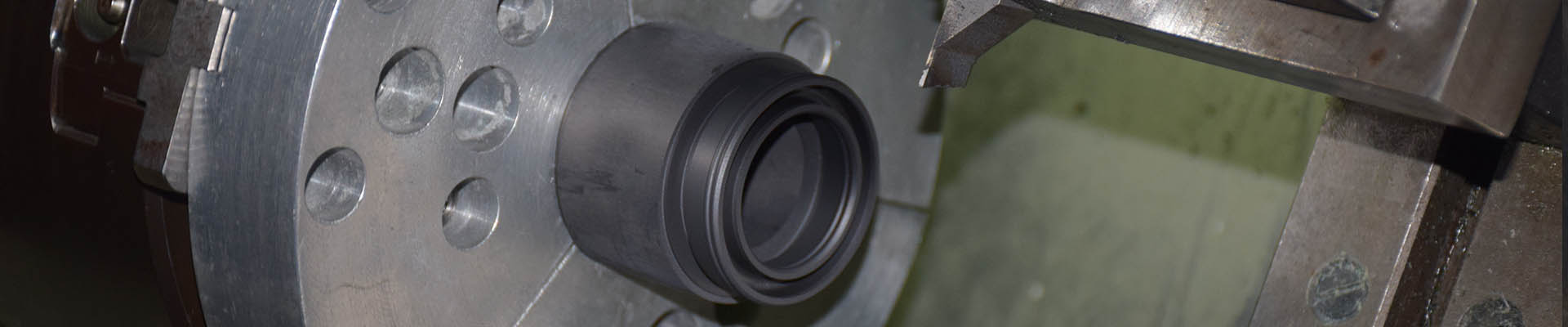

Les bagues d'appui en PEEK (polyétheréthercétone) et en PTFE (polytétrafluoroéthylène, communément appelé Téflon) jouent toutes deux un rôle important dans les applications d'étanchéité, mais présentent des différences significatives en termes de propriétés matérielles et d'avantages applicatifs. Voici leurs différences et leurs avantages respectifs :

1. Différences dans les propriétés des matériaux

Résistance et rigidité : le PEEK présente une résistance mécanique et une rigidité élevées, une bonne résistance à l'usure et peut conserver sa forme dans des environnements à haute pression.

Résistance aux hautes températures : le PEEK a une excellente résistance aux hautes températures et peut fonctionner en continu à des températures allant jusqu'à 250°C.

Stabilité chimique : le PEEK présente une bonne résistance à une variété de produits chimiques, mais peut subir certains effets dans des environnements acides et alcalins forts.

Conductivité : Le PEEK est un matériau semi-conducteur et peut parfois être utilisé dans des environnements sensibles aux décharges électrostatiques (ESD).

Bagues d'appui en PTFE :

Faible coefficient de frottement : le PTFE a un coefficient de frottement extrêmement faible et constitue un matériau idéal pour réduire le frottement.

Excellente stabilité chimique : le PTFE présente une excellente résistance à presque tous les produits chimiques et reste stable même à des températures élevées et dans des environnements corrosifs.

Résistance aux basses températures : le PTFE résiste non seulement aux températures élevées, mais également aux basses températures, et peut fonctionner dans la plage de températures de -200°C à 260°C.

Non-adhérence : Presque aucune substance n'adhère à la surface du PTFE et n'est pas facilement contaminée.

2. Avantages de l'application

Avantages de la bague de secours PEEK :

Environnement haute pression : la résistance et la rigidité élevées du PEEK lui permettent de bien fonctionner dans les environnements haute pression et conviennent aux systèmes hydrauliques, aux vannes haute pression, etc.

Applications à haute température : la résistance à haute température du PEEK lui confère des avantages dans les environnements à haute température, tels que l'industrie aérospatiale, l'industrie automobile et l'industrie chimique.

Propriétés mécaniques : Les bonnes propriétés mécaniques et la résistance à l'usure du PEEK lui permettent d'être performant dans les environnements nécessitant un travail de longue durée et de haute intensité.

Avantages de Bague de support en PTFE :

Environnements chimiquement corrosifs : La stabilité chimique du PTFE en fait un choix idéal dans les environnements chimiquement corrosifs, tels que les équipements de traitement acide et alcalin, les pipelines chimiques et les vannes.

Applications à faible frottement : le faible coefficient de frottement du PTFE le rend excellent dans les applications où le frottement et l'usure doivent être réduits, comme dans les roulements, les joints et les segments de piston.

Large plage de températures d'application : la large plage de températures du PTFE le rend adapté à une variété d'environnements allant des températures extrêmement basses aux températures élevées.

3. Guide de sélection

Choisissez les bagues d'appui PEEK : si vous avez besoin de propriétés d'étanchéité à haute résistance, à haute température et résistantes à l'usure, en particulier dans les environnements à haute pression et à haute température, le PEEK est un choix idéal.

Choisissez la bague de support en PTFE : si vous avez besoin d'une excellente stabilité chimique, d'un faible coefficient de frottement et d'une large plage d'adaptabilité à la température, en particulier dans les environnements de corrosion chimique et à basse température, le PTFE est un meilleur choix.

En résumé, Joint PEEK et le joint PTFE ont chacun leurs propres avantages, et le matériau à choisir dépend de l'environnement d'application spécifique et des exigences de performance.

Nouveau blog

© droits dauteur: 2026 Guangzhou JST Seals Technology Co., Ltd. Tous les droits sont réservés.

Numériser vers WeChat