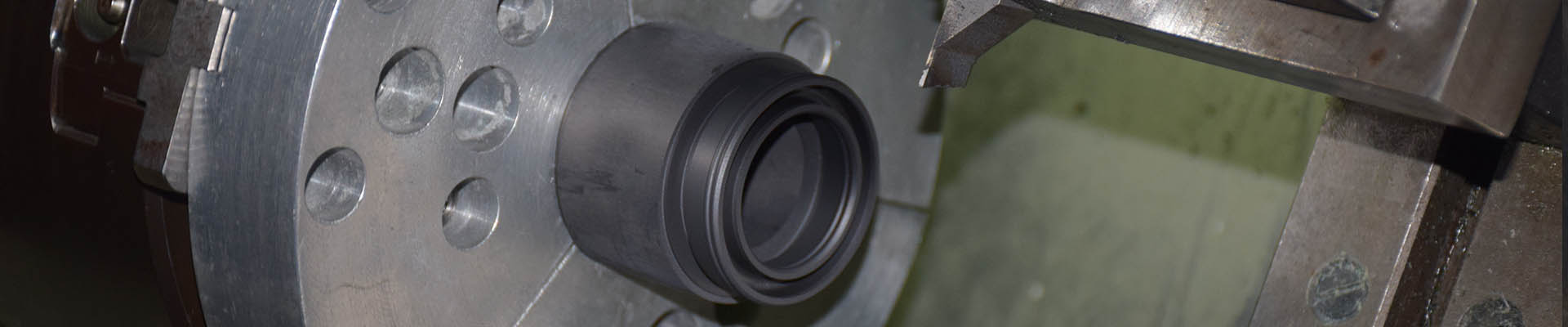

Garniture de pompe à piston pour puits de service

joue un rôle crucial dans le

industrie pétrolière et gazière

, notamment dans les opérations d'entretien des puits.

1. Fonction

La fonction principale de

garniture de pompe à piston

Son rôle est de créer une étanchéité fiable entre le piston et le cylindre de la pompe. Elle empêche les fuites de fluides tels que la boue de forage, les fluides de fracturation ou les fluides produits (mélanges de pétrole et de gaz).

2. Matériaux et construction

Ces garnitures sont généralement fabriquées à partir d'une combinaison de matériaux afin de résister aux conditions difficiles de l'exploitation des puits.

-

Élastomères : Des matériaux comme le caoutchouc nitrile (NBR) et le caoutchouc nitrile hydrogéné (HNBR) sont couramment utilisés. Le NBR offre une bonne résistance aux huiles et aux hydrocarbures et convient à une large plage de températures. Le HNBR offre une résistance accrue à la chaleur, aux produits chimiques et à l’abrasion, ce qui le rend idéal pour les applications plus exigeantes.

-

Composites renforcés par fibres : Des fibres telles que les fibres d’aramide sont parfois utilisées pour renforcer les matériaux de garnissage. Les garnitures renforcées en aramide présentent une résistance mécanique élevée et une bonne résistance à l’abrasion. Les fibres contribuent à maintenir l’intégrité de la garniture sous haute pression et en conditions de frottement élevé.

3. Caractéristiques de performance

-

Étanchéité : Les garnitures de haute qualité peuvent maintenir l'étanchéité même à des pressions extrêmement élevées, courantes dans les applications de services de puits telles que la fracturation hydraulique, où les pressions peuvent atteindre des milliers de livres par pouce carré.

-

Résistance à l'usure : La garniture de la pompe à piston est soumise à un frottement continu lors du mouvement de va-et-vient du piston dans le cylindre. Une bonne résistance à l'usure garantit une durée de vie plus longue.

-

Résistance chimique : Les fluides utilisés dans les puits peuvent contenir une grande variété de produits chimiques. Le garnissage doit résister à la dégradation et conserver ses propriétés d’étanchéité lorsqu’il est exposé à ces substances. Cette résistance chimique est essentielle au bon fonctionnement de la pompe à piston dans différentes situations d’entretien des puits.

-

Résistance à la température : La température peut varier considérablement en fonction de la profondeur du puits et de la nature de l’opération. Les garnitures des pompes à piston doivent fonctionner efficacement sur une large plage de températures. Par exemple, lors d’opérations en puits profonds, la température peut être très élevée et le matériau de la garniture doit conserver ses propriétés d’étanchéité et mécaniques sans se ramollir ni se durcir excessivement.

4. Application dans l'industrie pétrolière et gazière

Dans le secteur des services pétroliers et gaziers, les garnitures de pompes à piston sont utilisées dans diverses opérations.

-

Forage : Lors du forage, la pompe assure la circulation de la boue de forage. Le garnissage garantit l’étanchéité du système de pompage, assurant ainsi la stabilité du puits et le refroidissement et la lubrification du trépan.

-

Fracturation et acidification : La fracturation hydraulique consiste à injecter des fluides à très haute pression dans le puits afin de créer des fractures dans la formation rocheuse et ainsi accroître la production de pétrole et de gaz. Le garnissage de la pompe à piston doit résister à ces hautes pressions et à la nature corrosive des fluides de fracturation. De même, lors des opérations d’acidification, où des acides sont utilisés pour dissoudre les formations rocheuses et améliorer la perméabilité, le garnissage doit résister aux fluides acides.

Production et entretien des puits : Une fois le puits en production, la pompe à piston peut être utilisée pour les opérations d’entretien, comme le pompage de produits chimiques pour prévenir la formation de tartre ou pour nettoyer le puits. Le joint d’étanchéité assure un transfert efficace de ces produits chimiques sans fuite.

françaisfr

françaisfr françaisfr

françaisfr